Satellite Receiving Equipment

Satellink provides the design and manufacturing services for special items related to satellite receiving equipment and customer’s specific applications. This specialized service utilizes the control and remote interface communications standards as outlined by RS-489 and RS-232, as well as Ethernet capabilities. Products are suitable for a range of applications including satellite, communications, shipboard, airport surveillance, and radar. As with all Satellink products, integrity and quality are ensured with comprehensive inspections along with functional and physical verification testing.

All products are designed and manufactured by skilled engineers and technicians, and held to the highest industry standards including the Defense Federal Acquisition Regulation, Bureau of Industrial Security (BIS), FCC Compliance, and MIL-STD-215. Typical lead time for special items is 4-9 months, with possible production of 1 – 2000 units. Satellink has the experience to custom fabricate any item to meet today’s critical demands. Other value added services unique for our field include product development, evaluation, assembly, testing, alignment, and repair.

For more details about our specialized items for satellite receiving equipment, please see the table below or contact directly.

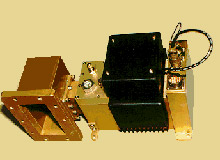

Examples of our Work

- Manufacturing of a UHF Diplexer Low Noise Amplifier

- Manufacturing of a Low Noise Amplifier Controller

- Manufacturing of a Multiple Channel Telemetry Frequency Converter

- Manufacturing of a Thermoelectrically Cooled K Band Low Noise Amplifier

- Manufacturing of a K Band Crygenically Cooled Low Noise Amplifier

- Manufacturing of a Phase Matched & Tracking Ku Band Low Noise Amplifier

Receiving Equipment Manufacturing Capabilities

Product Name

Satellite Receiving Equipment

Type

Special Items

Controls, Remote Interface Communications

RS-485

RS-232

Ethernet

Inspection

Visual (Microscope)

Scalar and Vector Network Analyzers

Noise Measurement

Frequency Counters

Spectrum Analyzers

Testing

Functional & Physical

Verification

Environmental Tests

Salt

Temperature

Fog

Humidity

Vibration, Shock

Radiation

EMI / RFI

Quality

Test Profile

Inspection Stamp

Additional Services

Engineering

Design

Development

Evaluation

Assembly

Test

Alignment

Repair

Production Volume

1 to 2000 units

Lead Time

4 to 9 months

Additional Information

Industry Focus

Aerospace

Communications

Electronics

Military

Telecommunications

Telemetry

Intended Applications

Satellites

Communications

Radar

Phased Array Antennas

Airport Surveillance

GCA

Airborne

Shipboard

Mobile

Fixed

Industry Standards

ISO 9001:2015

IPC-A-610 Workmanship

IPC-J-001

ANSI NCSL Z540-I-1994

ITAR Licensed

Defense Federal Acquisition Regulation

Bureau of Industrial Security (BIS)

FCC Compliance

MIL-STD-215

File Formats

AutoCAD

SolidWorks